Manufacturing the Arnold & Son LUNA MAGNA 3D Moon

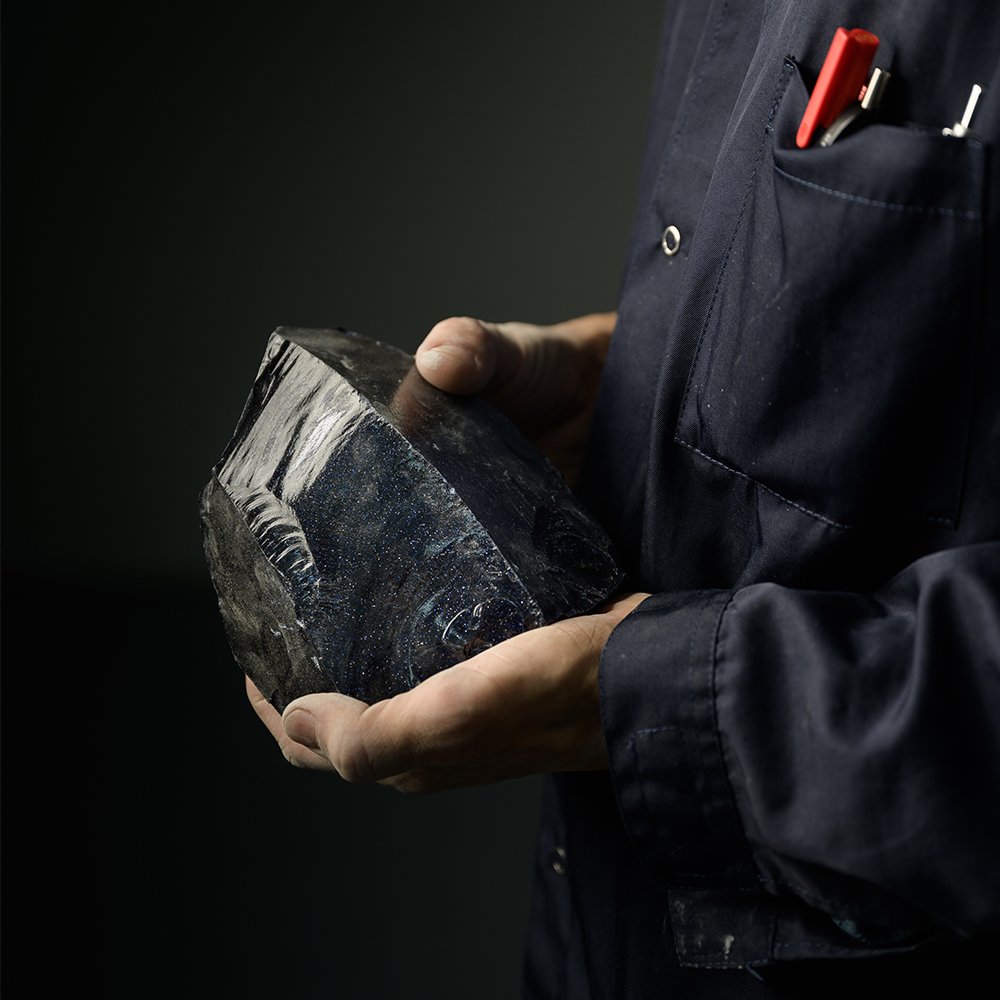

Step 1 - Choosing the appropriate raw material

Selection of the right area for:

- Color

- Structure and homogeneity

- Glittering effect (Aventurine glass) to match perfectly with the dial.

Step 2 - Coring process

Define the sector that match the aesthetic and design requirements;

- Veining for the Adriatic white marble to interpreted the shades of the moon.

- Density of metallic oxide splinters.

Artisans pay attention to the pressure when coring the mineral stones, to much pressure would mean cracks.

Step 3 - Slicing process

Slicing the mineral cylinder to obtain straight faces and adapted height.

This operation requires a lot of ability in regards of the sharp cutting disc!

Step 4 - Inside face drilling process

Our artisans had to:

- Research the adapted drilling tools for these specific mineral materials.

- Identify the good drilling parameters (rotation and progressing speeds) for such precise and tiny details.

The perfect parameters will avoid any chips (edge break, damage) which would immediately cause a quality and aesthetic issue.

This process duration requires at least 2,5 hours of drilling per pieces.

Step 5 - Outside face rounding process

The moment of truth - Rounding the outside surface is the most delicate step with potentially the highest ratio of defect pieces:

- Cracks could appear at any time due to the thin thickness enduring this operation.

- Any hidden cavity would immediately show off.

The surface rounding takes 3 hours of machining for each single piece.

Step 6 - Polishing process

Polishing the outer surface is the last mechanical step.

The hand movements will give the expected polished aspect of our perfect half domes.

Years of experiences will guarantee any surface deformation.

Step 7 - Pre-assembly process

All dimensions of each half domes are controlled to ensure the perfect assembly between the two sides.

The engaging axle must fit in between with absolutely any room.

Step 8 - Assembly Process

The assembly step is the final operation to achieve Arnold & Son three-dimensional moon.

The axle is put in place and the two mineral parts are clipped together and secured with a drizzle of epoxy compound.

The curing time is about 4 to 5 hours.

Step 9 - Ready to mount in the movement

Finally, after more than 2 days of craftmanship, the unique Arnold & Son 3D moon made of mineral stones is achieved.

Our quality experts will then go through all details and validation process before adding it to our new Luna Magna caliber.